How to Replace a Serpentine Belt on the Roadside: Step-by-Step

Introduction to Serpentine Belt Replacement Roadside Challenges

Alright folks, picture this: you're cruising down the highway, windows down, tunes blasting, and BAM! Your car starts making this ungodly screeching noise. Your power steering's gone, your AC's blowing hot air, and your heart sinks. Sounds like a broken serpentine belt, doesn't it? Don't panic! Replacing it on the roadside might seem daunting, but with a little know-how and the right tools, you can get back on the road in no time. This guide is your lifeline. We'll walk you through it, step-by-step.

Essential Tools and Safety Precautions for Serpentine Belt Replacement

Before you even think about popping the hood, gather your gear. You'll need:

- A new serpentine belt (Make sure it's the right one for your car! Check your owner's manual or a parts store.)

- A wrench or socket set (Metric or SAE, depending on your car)

- A breaker bar (For extra leverage if the tensioner is stubborn)

- A diagram of your serpentine belt routing (Crucial! Take a picture before you start if you're unsure.)

- Gloves (Protect those hands!)

- Safety glasses (Seriously, protect your eyes!)

- A flashlight or headlamp (Especially if it's getting dark)

- A piece of paper and a pen (To sketch the belt routing if you can't find a diagram)

- Jack and Jack Stands(for safe access if needed)

Safety First! Always work on a cool engine. A hot engine can cause serious burns. Disconnect the negative battery terminal to prevent any electrical mishaps. And if you need to jack up the car, use jack stands – never rely solely on the jack!

Step-by-Step Guide Replacing Your Serpentine Belt On The Road

- Locate the Serpentine Belt and Tensioner: The serpentine belt snakes around various pulleys on the front of your engine. The tensioner pulley is spring-loaded and keeps the belt tight. It usually has a square opening or a bolt head that you can use to relieve the tension.

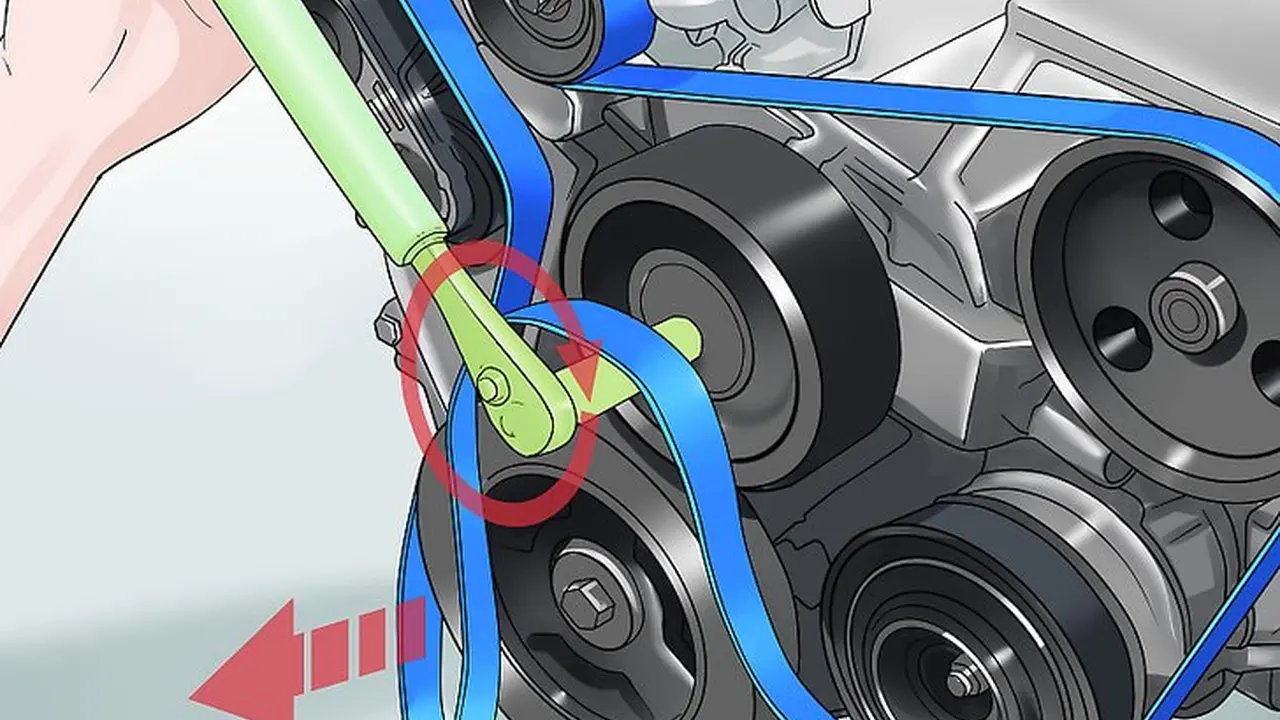

- Relieve the Tension: Using your wrench or socket, insert it into the tensioner. Apply steady pressure to rotate the tensioner. This will loosen the belt. You might need a breaker bar for extra leverage if it's really tight.

- Remove the Old Belt: While holding the tensioner in the loosened position, carefully slip the belt off one of the pulleys. Then, remove the rest of the belt from all the pulleys. Take a good look at the old belt. Are there cracks, fraying, or missing chunks? This can give you clues about potential issues with other components.

- Route the New Belt: This is where your diagram (or photo) comes in handy. Following the routing diagram, carefully thread the new belt around all the pulleys EXCEPT the tensioner pulley. Make sure the belt is seated correctly in the grooves of each pulley.

- Re-engage the Tensioner: Using your wrench or socket, rotate the tensioner again to relieve the tension. Slip the new belt over the tensioner pulley.

- Release the Tensioner: Slowly release the tensioner, allowing it to spring back into place. Double-check that the belt is properly seated on all the pulleys.

- Inspect and Test: Give the belt a good visual inspection. Make sure it's aligned correctly and that there are no twists or kinks. Reconnect the negative battery terminal. Start the engine and listen for any unusual noises. Check that your power steering, AC, and other accessories are working properly.

Serpentine Belt Problems Diagnosis and Troubleshooting

Sometimes, a new belt doesn't solve the problem. Here are a few things to consider:

- Squealing Noise: Could be a misaligned belt, a worn pulley, or a faulty tensioner.

- Belt Slippage: Check for oil or coolant leaks that might be contaminating the belt. Also, ensure the tensioner is providing adequate tension.

- Belt Breaking Repeatedly: Could indicate a seized pulley or a more serious engine problem.

Recommended Serpentine Belts for Roadside Replacement

Choosing the right serpentine belt is crucial for reliability and longevity. Here are a few recommendations:

- Gates Micro-V Serpentine Belt: Known for its durability and resistance to cracking. A great all-around choice. Typically costs around $20-$40.

- Goodyear Gatorback Serpentine Belt: Designed for high-performance applications and extreme temperatures. A bit pricier, around $30-$50.

- Bando Serpentine Belt: A reliable and affordable option, often used as original equipment on many vehicles. Generally priced between $15-$35.

Usage Scenarios:

- Gates: Ideal for everyday driving and moderate climates.

- Goodyear Gatorback: Best for trucks, SUVs, and vehicles that experience heavy use or operate in hot climates.

- Bando: A good value choice for budget-conscious drivers.

Product Comparison:

| Belt Brand | Durability | Temperature Resistance | Noise Level | Price Range |

|---|---|---|---|---|

| Gates Micro-V | Excellent | Good | Low | $20-$40 |

| Goodyear Gatorback | Superior | Excellent | Slightly Higher | $30-$50 |

| Bando | Good | Average | Low | $15-$35 |

Serpentine Belt Tensioner Pulley Inspection and Replacement Tips

Don't forget about the tensioner! A worn or faulty tensioner can cause premature belt wear and failure. Check for excessive play, noise, or wobbling. If it's suspect, replace it along with the belt. A new tensioner typically costs between $50 and $100.

Dealing with Stuck or Hard-to-Reach Serpentine Belt Tensioners

Sometimes, the tensioner can be a real pain to access. Here are a few tips:

- Use a Breaker Bar: Provides extra leverage for stubborn tensioners.

- Penetrating Oil: Spray some penetrating oil on the tensioner pivot point to loosen it up.

- Different Wrench Angles: Try using a different wrench or socket with a swivel adapter to get a better angle.

Preventative Serpentine Belt Maintenance for Long Lasting Performance

A little preventative maintenance goes a long way. Inspect your serpentine belt regularly for signs of wear. Keep the engine bay clean and free of debris. And replace the belt according to your vehicle manufacturer's recommended service interval (usually every 60,000 to 100,000 miles).

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)